top of page

24hour hotline(WhatsApp) +86 13831107620

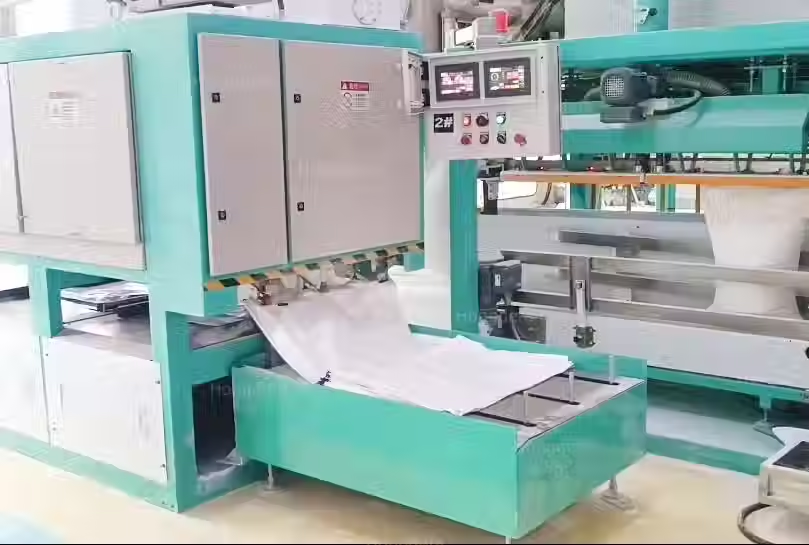

Working Process of Fully Automatic Packing Machine

1

2

3

Technical parameters of packaging machine

--- Product parameters

1. External dimensions: 5500mm × 3200mm x 5000mm

2. Packaging category: woven bags

3. Packaging specifications: 25-50kg

4. Overall power: 25kw (operating power: approximately 15kW)

5. Power supply: TN-S 380V 50Hz

6. Gas source: pressure P ≥ 0.6MPa, gas volume Q≥ 27m³/h

7. Measurement accuracy: FS ± 2%.(Dynamic)

8. Filling speed: 550 bags/hour

9. Environmental temperature: -10°C ~ 40 °C

10. Dust removal air volume: Dedusting

--- Applicable scope:

Fiber, plumule, bran and other flaky materials

* Product parameters

1. External dimensions: 4185mm x 2400mm x 5500mm

2. Packaging category: Woven bags

3. Packaging specification: 40-50kg

4. Sewing method: Edgefold and seam.

5. Packaging speed: ≥400Bags/hour

6. Measurement accuracy: FS ± 2%(Dynamic)

7. Whole machine weight: 2t

--- Applicable scope:

Corn starch, amino acids, glucose, alginate andother powdered materials

** Product parameters

1. External dimensions: 6500mm × 4000mm × 5500mm

2. Packaging category: Woven bags

3. Packaging specifications: 25~50kg

4. Power of the whole machine: 13kW

5. POWER SUPPLY: TN-S 380V 50Hz

6. Gas source: pressure P ≥ 0.6MPa, gas volume Q ≥ 6m³/h

7. Measurement accuracy: FS ± 2%(Dynamic)

8. Speed of packaging: ≥ 400 bags/hour

9. Dedusting air volume: 500 m³/h

Key Advantages

1. Complete Automation:

Handles filling, weighing, sealing, and more without manual intervention.

2. Ultra-High Speed:

Optimized for high-volume production, maximizing throughput.

3. Exceptional Accuracy:

Advanced weighing and control systems ensure precise measurements and consistent bag weights.

4. Space-Saving Design:

Compact and modular construction optimizes floor space in your facility.

5. Hygienic and Safe:

Built with stainless steel and food-grade materials, meeting strict hygiene and safety standards.

6. Energy Efficiency:

Reduces operational costs by minimizing energy consumption.

Why Choose Shijiazhuang Hongdefa Machinery?

1. Expertise: Rich experience in manufacturing high-quality milling and packaging machines.

2. Customization: Tailored solutions to meet your specific production needs.

3. Comprehensive Support: End-to-end service, from installation to after-sales support.

bottom of page